SLV – Schweißtechnische Lehr- und Versuchsanstalten

Stud welding

Within the framework of training measures and procedure qualification tests according to DIN EN ISO 14555, operators and welding coordinators can obtain qualifications in the field of stud welding (arc stud welding and friction stud welding).

Range of services on offer

- Advice about solving stud welding problems

- Individual development services (also together with a device manufacturer)

- Assessment of the welding quality

- Optimisation of your welding task

- Operator qualification tests according to DIN EN ISO 14732

- Procedure qualification tests for stud welding according to DIN EN ISO 14555

- Neutral investment advice

- Creation of prototypes and pilot series

Also ask us about individual training for you and your employees!

Information about arc stud welding

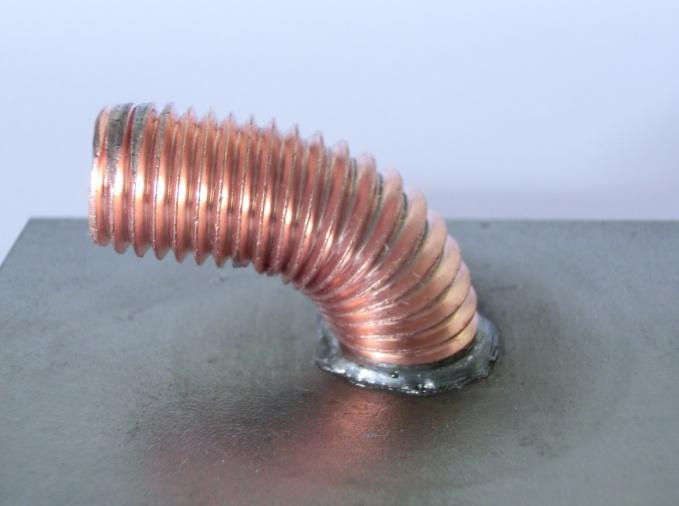

Pin-shaped metallic components with diameters up to approx. 25 mm are fastened on base sheets vertically by means of stud welding. Different procedure variants are available for the most diverse applications.

- The stud welding procedures are generally characterised by high economic viability and good automatability.

- The usable materials and material combinations are restricted in the case of arc stud welding. A wide variety of materials and material combinations can be joined using friction stud welding.

- Applications can be found in all fields of the metal processing industry.

In the case of arc stud welding, an arc burns between the front face of the stud and the workpiece for a short time and partially melts the joining members (stud and sheet). After sufficient partial melting, the molten pools are connected with each other by the stud movement towards the sheet.

Depending on the procedure variant, the stud welding industry offers suitable power sources, movement jigs, studs and additional auxiliary materials (e.g. ceramic ferrules). The handling is comparatively simple but a large number of welding and boundary conditions must be coordinated in practice for successful and safe fabrication.

Our technical equipment

In our laboratory rooms, we have at our disposal stud welding installations for the drawn arc and initial contact procedures as well as for the friction stud welding of various designs and sizes.

In this respect, the performance range of the installations extends from thin pins (approx. 2 mm) to massive head studs (approx. 25 mm).

The field is looked after by three people (two engineers and one technologist).

- Drawn arc stud welding (ceramic ferrule or shielding gas)

- Initial contact stud welding (gap and contact variants)

- SRM technology

- Magnetically impelled arc sleeve or nut welding

- Friction stud welding

- Process monitoring with suitable testing devices

Contact person

SLV Berlin-Brandenburg

- Matthias Pöge

- +49 30 45001-113

- matthias.poege(at)slv-bb.de

SLV Duisburg

- Walter Bockting

- +49 203 3781-186

- bockting(at)slv-duisburg.de

SLV Fellbach

- Daniel Rotaru

- +49 711 57544-48

- office(at)slv-fellbach.de

SLV Hannover

- Karsten Schnoy

- +49 511 219 62-67

- schnoy(at)slv-hannover.de

SLV Mannheim

- Michael Schubert

- +49 621 3004 122

- schubert(at)slv-mannheim.de

SLV München

- Michael Dey

- +49 89 126802-12

- dey(at)slv-muenchen.de

SLV Saarbrücken

- Bernd Stiefel

- +49 681 58823-47

- stiefel(at)slv-saar.de